Should you hire an Interior Designer?

Hiring an interior designer can be a great investment for homeowners looking to renovate or redecorate their home. Not only can a designer help you create a beautiful and functional space, but they can also save you time and money in the long run. In this article, we’ll explore the benefits of hiring an interior designer and discuss when it might make sense to bring one on board for your next project.

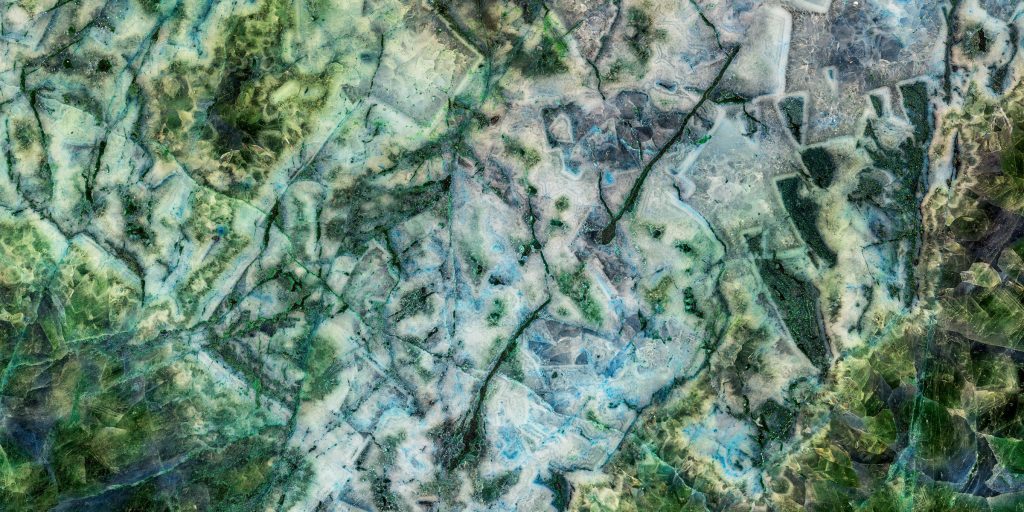

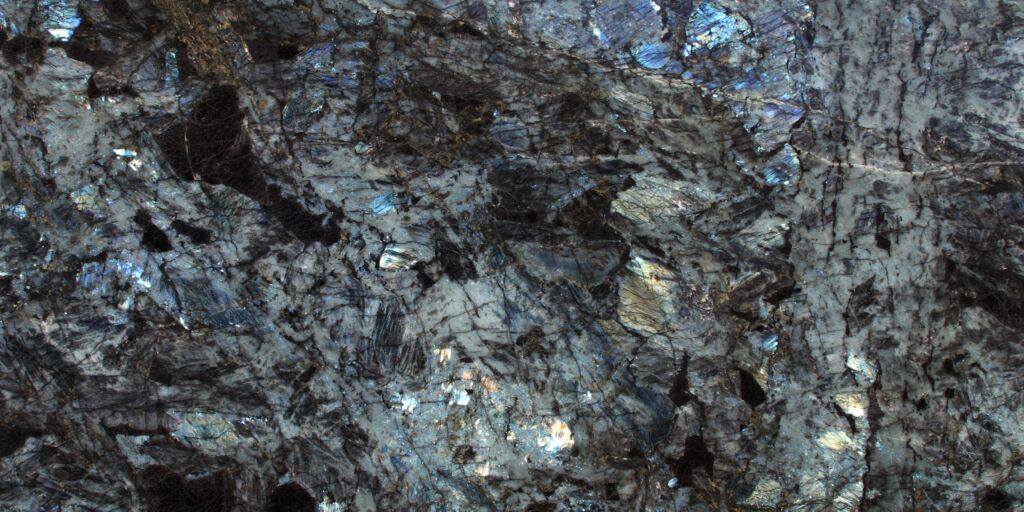

One of the main benefits of hiring an interior designer is that they can help you create a cohesive and well-designed space. Interior designers are trained professionals who understand the principles of design, such as color theory, space planning, and lighting. They can help you choose the right furniture, accessories, and materials to create a space that is both beautiful and functional. A designer can also help you make the most of your space, whether it’s a small apartment or a large house.

Another benefit of hiring an interior designer is that they can save you time and money. A designer can help you avoid costly mistakes, such as purchasing furniture that is too big or too small for your space. They can also help you find the best deals on materials and furnishings, which can save you money in the long run. Additionally, a designer can help you stay on schedule and within budget during your renovation or redecoration project.

When it comes to deciding whether or not to hire an interior designer, it’s important to consider your specific needs. If you’re planning a large-scale renovation or remodel, such as a kitchen or bathroom renovation, it may make sense to bring on a designer to help you plan and execute the project. If you’re simply looking to redecorate a room or two, you may be able to handle the project on your own.

One factor to consider is your budget. Hiring an interior designer can be expensive, and it may not make sense for you to invest in one if you’re working with a limited budget. However, keep in mind that a designer can help you save money in the long run by avoiding costly mistakes and finding the best deals on materials and furnishings.

Another benefit of hiring an interior designer is that they can help you create a personalized space that reflects your personal style and tastes. A designer can work with you to understand your design preferences and create a space that is tailored to your specific needs and desires. They can also help you incorporate your personal items, such as artwork and photographs, into the design of your space to create a truly personalized and unique look.

An interior designer can also help you to make your home more livable and functional. They can help you to create a space that is comfortable, efficient and easy to use. They can also help you to create a space that is easy to maintain, and that will stand the test of time. They know the best materials, colors and furniture suitable to a specific area, and will use their expertise to make your home more enjoyable.

Finally, hiring an interior designer can also be a great way to increase the value of your home. A well-designed and well-executed renovation or redecoration project can significantly increase the value of your home. A designer can help you to make smart design choices that will appeal to potential buyers and help you to get the most out of your investment.

Overall, hiring an interior designer can be a great investment for homeowners looking to renovate or redecorate their home. Not only can a designer help you create a beautiful and functional space, but they can also save you time and money in the long run. When deciding whether or not to hire an interior designer, consider your specific needs, budget, and the scope of your project. With the right designer, you can transform your home into a beautiful, livable space that you’ll enjoy for years to come.